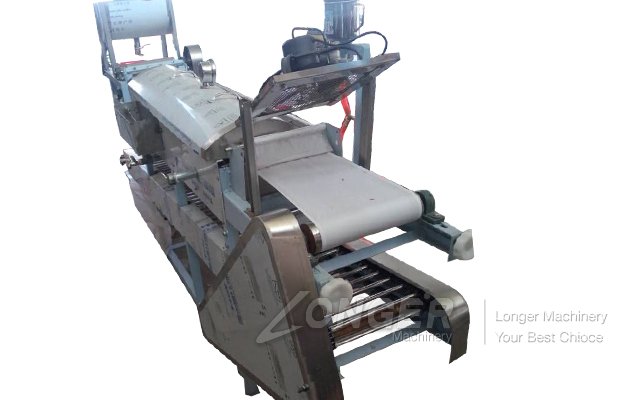

Fried Rice Noodle Making Machine Manufacturer

MOQ:1 set

Brand:LONGER MACHINERY

Certification: CE

Supply Ability:200 sets per month

PAY METHOD: WEST UNION L/C T/T CASH

Warranty Time:12 Months

LOADING PORT: Qingdao

Country Of Origin: China

The fried rice noodle making machine is mainly used for filling the grind rice milk into the machine, and though the machine for steaming, cutting, and then cooling into cold rice noodle; Cold Rice Noodle’s raw material is rice, rice after washing and grinding into powder, add water into the powder to make rice paste, steamed into rice noodle. The original rice noodle is white, but you can add the vegetable juice or fruit juice to made colorful and nutrient-rich rice noodle.

There have some tips to make the fresh, delicious rice noodle, attention: When you handle the raw material, you should washing the rice before soaking, and control soak time reasonably; unseasoned and final product can’t be put on the same place; All the container for putting the rice noodle should clean and dry to extend the shelf-life; When the rice noodle steaming, you’d better keep flat and don’t turn them to keep the smooth surface. Suitable for chinese restaurant, characteristic snack bar,etc..

Advantages:

1. All imports of stainless steel, flow lines and comfortable, clean and beautiful, durable;

2. Using direct thermal heating, heating up fast, low fuel consumption than ordinary rice noodle machine saving more than 40%;

5. Production speed, thickness and temperature control, etc., can be adjusted;

6. Complete preservation of the nutritional content of rice, ho fun noodles good quality, not only nutritious, but also the health and delicious;

7. Spindle use special steel, and the strict heat treatment, make its significantly longer service life;

8. Spindle bold, extended, and motor power, and to greatly improve the yield;

9. Dashboard and the workbench is installed in the same position.

| Model | LG-50 | LG-60 | LG-80 | LG-120 | LG-150 | LG-250 | LG-350 | LG-500 |

|

Capacity (kg/h) |

50 | 60 | 80 | 120 | 150 | 250 | 350 | 500 |

| Power(kw) | 0.55 | 0.55 | 0.55 | 0.55 | 0.75 | 0.75 | 0.75 | 0.75 |

| Voltage(V) | 220 | 220 | 220 | 220 | 220 | 220 | 220 | 220 |

|

Dimension (m) |

2.6*0.6*1.2 | 2.9*0.6*1.2 | 3.7*0.7*1.2 | 4.1*0.7*1.2 | 4.1*0.9*1.2 | 5.7*0.9*1.2 | 5.8*1.1*1.2 | 8.5*1.1*1.3 |

Leave Your Message

Leave Your Message Home

Home