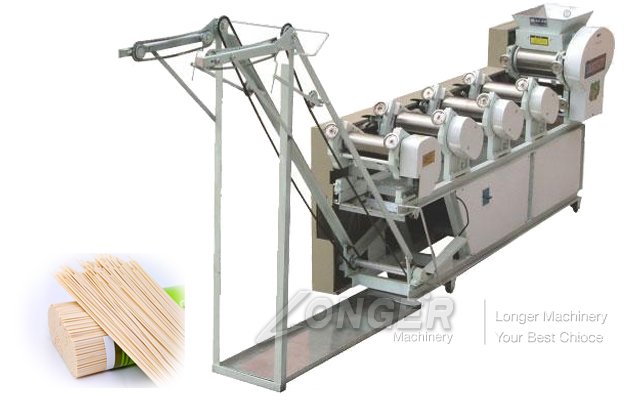

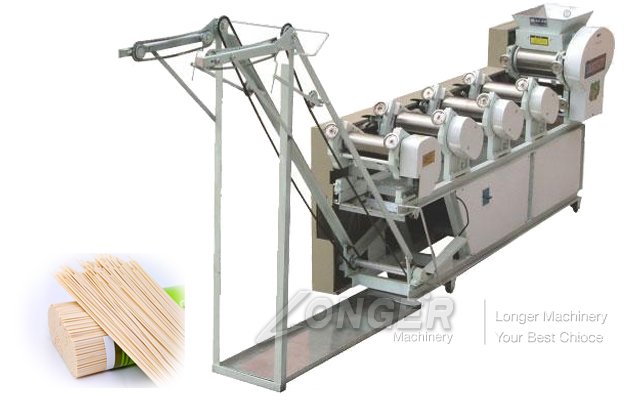

Noodle maker machine can also be put into noodle production line to use, which can connect with drying line. Whole process can be finished automatically. As to the noodle molding knifes, we can customize the forming width of knifes according to customers’ emands; The knifes can be changed to get the noodles with different size easily when needed, But there are also something that should be paid more attention for safe operation.

Key points for safe operation of noodle machine:

Key points for safe operation of noodle machine:

1. The operator should carefully study the instruction before use, strictly follow the requests of instruction Manual;

2. The machine is strictly forbidden to reverse;

3. Before start, check all parts exist abnormal phenomenon or not, find the problem, and handle it in time to avoid accidents;

4. To prevent iron or other hard material from mixing with flour, so as to avoid mechanical damage.

5. When the machine is running, HANDS are prohibited dipping into the roller, gear, chain, cutter, and other dangerous parts;

6. Ensure the rotating parts of lubrication, oil scale, cup, gears, chain on each site of the oil hole, each class second filling No. 20 - 30 No. oil, cut blade surface, the surface of the roller end of each class, add a little cooking oil.

7. No other hard debris into the roller and gear;

8. It is strictly prohibited to roll gap to 5 mm or more for operation.

Next:Characteristics Analysis For Chinese Noodle Machinery Industry