Features

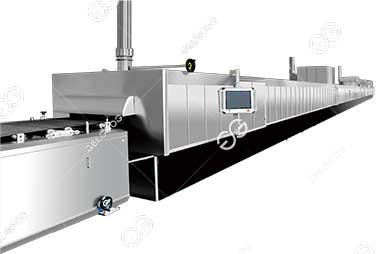

Industrial tunnel oven structure

Heating system: Electric heating, gas heating, and other heating methods can be used to generate the required heat.Conveying system: Usually composed of stainless steel mesh belt, chain or roller, used to continuously convey products through the tunnel oven at a constant speed to ensure the continuity of the production process.

Control system: It is composed of thermostat, timer, speed regulator, etc., which can accurately control process parameters such as temperature, conveying speed, baking time, etc. Some advanced control systems also have functions such as intelligent monitoring and fault diagnosis.

Insulation shell: Made of materials with good insulation performance such as steel plate and insulation cotton, it reduces heat loss, saves energy, and ensures safe operation.

Application field of industrial tunnel oven

Food industry: It is used for large-scale production of baked foods such as bread, biscuits, cakes, etc., and can also be used for drying and dehydration of meat, fruits, etc.

Advantages of tunnel oven for sale

High level of automation: It enables continuous production processes, enhances production efficiency, and lowers labor expenses.Advanced temperature control: It features a sophisticated temperature control system that can precisely regulate the temperature within the oven, ensuring consistent product quality.

Uniform heat distribution: Utilizing hot air circulation or other heating techniques ensures a uniform temperature profile throughout the furnace, preventing localized overheating or underheating of the product.

High customizability: It can be tailored to meet diverse production requirements, with options for different sizes, specifications, heating methods, and control systems.

Technical Data

FAQ

industrial tunnel oven FAQ

What are the common heating methods for tunnel ovens, and what are their advantages and disadvantages?

Common heating methods include gas heating and electric heating. Gas heating has relatively low cost and high thermal efficiency, but requires a gas supply system; electric heating is clean and environmentally friendly, and temperature control is precise, but the operating cost may be high.

How to choose a suitable tunnel oven according to production needs?

Factors such as production scale, product type and size, process requirements (such as temperature range, uniformity, etc.), energy supply, budget and workshop space need to be considered.

What specifications and models are available for tunnel ovens?

There are usually multiple length, width and height specifications, such as length ranging from 6 meters to 30 meters, width may be between 0.8 meters and 2 meters, and height generally ranges from 0.5 meters to 1.5 meters, depending on production needs.

What are the common heating methods for tunnel ovens, and what are their advantages and disadvantages?

Common heating methods include gas heating and electric heating. Gas heating has relatively low cost and high thermal efficiency, but requires a gas supply system; electric heating is clean and environmentally friendly, and temperature control is precise, but the operating cost may be high.

How to choose a suitable tunnel oven according to production needs?

Factors such as production scale, product type and size, process requirements (such as temperature range, uniformity, etc.), energy supply, budget and workshop space need to be considered.

What specifications and models are available for tunnel ovens?

There are usually multiple length, width and height specifications, such as length ranging from 6 meters to 30 meters, width may be between 0.8 meters and 2 meters, and height generally ranges from 0.5 meters to 1.5 meters, depending on production needs.

Message

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.